‘Crown Jewels’ Ready for Telescope

June 1, 2020

Sophisticated set of mirrors will sharpen, widen HET’s view of the sky.

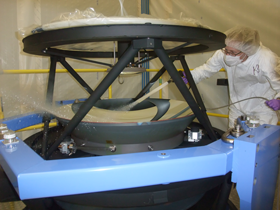

The “crown jewels” of the Hobby-Eberly Telescope upgrade — a set of four mirrors designed to sharpen the view to pinpoint precision — have been installed on the telescope. They soon will allow scientists to take their first views of the night sky with the refurbished HET.

The corrector is designed to meet that challenge. Its four mirrors — three of which are roughly one meter (three feet) in diameter — were carefully shaped to sharpen the view. They also increase the telescope’s field of view to 22 arcminutes, so HET will see a region of sky that covers roughly half the size of the Moon — more than five times larger than its original field of view.

Finally, the corrector will allow scientists to use the full 10 meters (33 feet) of HET’s primary mirror. Originally, they could use no more than 9.2 meters during any single observation. “We got a bonus from the corrector — the telescope just got bigger,” says Hill.

The corrector was built by the University of Arizona College of Optical Sciences in Tucson — a process that took five years. Much of the time was required for alignment and testing. “This is the most complicated optical assembly ever built for astronomy,” says Hill. “The components had to be aligned within one-tenth the diameter of a human hair, which is extraordinary. So the complexity of the testing was quite impressive.”

Since engineers couldn’t test the corrector on the telescope itself, they developed a sophisticated test rig that used laser light, holograms, and computer algorithms to simulate the primary mirror.

Hanshin Lee, the optical engineer with HETDEX, played a key role in analyzing the alignment data and predicting the on-sky performance of the corrector. The assembly passed its final tests in Tucson in May.

Transporting the corrector from Tucson to McDonald Observatory — a trip of more than 500 miles — required careful planning and preparation as well. The corrector was sealed against dust and humidity and wrapped inside a thermal blanket to keep its temperature constant during the long drive, mounted atop shock-absorbing springs, and housed inside a custom-built shipping container. “It was a lot of effort, but for something that cost about $6 million, it was worth it,” says Hill.

The package left Tucson on the evening of May 27, escorted by HETDEX personnel and a University of Texas at Austin police car.

After arriving at McDonald, it was carefully unpacked inside the HET dome. Lee then led the site testing of the corrector to ensure that it had arrived unscathed. The installation crew spent several weeks choreographing and rehearsing the steps required to raise the corrector to the top of the telescope and lock it in place inside the new tracking system.

Final testing will start when the refurbished HET takes its first look at a star. When that process is completed, the scientific instruments will be tested and verified, allowing HET to return to service — with a sharper and wider view of the sky.